More than two-thirds of fashion brands ‘washing their hands’ of exploited female labour

Women workers in India, Nepal, and Pakistan making clothes in their own homes for global fashion brands are earning less than two dollars per day and in some cases as little as 80p per day, new research shows.

This is below the average daily wage for a garment factory worker in those countries, which ranges between $10 to $3. The same research reports that women have to work 5-7 days per week when work comes in, because they are paid per item, and have no guarantee of regular work.

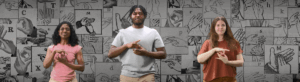

At least 12 million workers in South Asia work from their own homes cutting, packing and sewing clothes for global and national fashion brands, the majority without employment contracts. The Wage Analysis of Home-based workers in South Asia report, published this week by HomeNet South Asia and Transform Trade, coincides with Unseen Stories, a new online and offline photography exhibition featuring photographs taken by members of a homeworkers collective in Tamil Nadu, India, documenting their lives.

‘Without a paper trail these women workers are invisible, despite playing an essential role in fashion supply chains by supplementing factory production. If you genuinely want to stamp out exploitation, a homeworker policy is a basic starting point, alongside transparency about how you apply it,’ said Transform Trade CEO Charlotte Timson

Two-thirds of global fashion brands have no policy around homeworking, even though millions of women across South Asia make clothes from home for garment supply chains. Of those top brands that do have a homeworker policy, only 9% explain publicly how that policy is implemented, according to the latest Fashion Transparency Index.

Many women rely on homeworking because it enables them to balance caring responsibilities with earning an income, which is impossible in factories. E Suriya, a homeworker with homeworking collective Anukatham in Tamil Nadu, south India, and whose photography is featured in the exhibition, said: ‘I worked in a factory setting for three years, till my daughter was born. It was suffocating, I had to be there close to 12 hours a day. I wouldn’t get time for myself, couldn’t even take care of household work. Here, as a homeworker I can do both.’

The majority of major UK brands do have a published homeworker policy. The Stand with Homeworkers campaign, launched this summer, aims for all major British fashion brands to publish a homeworking policy and pledge to survey homeworkers in their supply chains, as a first step towards improved pay and conditions for these workers.

‘Homeworking doesn’t go away when you don’t acknowledge it. The fashion industry would grind to a halt without homeworkers and banning it forces it underground,’ said Timson. ‘What these homeworkers need is a paper trail, regular work, fair pay and basic social protections such as sickness and maternity pay. For that to happen, brands need to play their part and stop washing their hands of these workers.’

Most of fashion’s homeworkers are drawn from the most marginalised communities in Bangladesh, India, Nepal, and Pakistan. They are typically employed informally by subcontractors, are paid piece rates and have no contracts.

Transform Trade has worked alongside homeworker advocacy organisations including Homeworkers Worldwide to map supply chains down to the homeworker level, and help fashion brands introduce simple systems that document homeworkers’ contribution and wages. With support from the European Union, the project has put together a toolkit for brands and suppliers wanting to address homeworkers’ labour rights.

‘Homeworking provides vital income for millions of women unable to access factory work – for childcare, health, geographical or cultural reasons,’ said Peter Williams, policy lead with Homeworkers Worldwide. ‘Recognising homeworkers as workers is the first step to ending their exploitation and abuse. Brands need to recognise the valuable contribution of homeworkers, first through adopting an inclusive policy and then implementing it by working with their suppliers to improve transparency and working conditions.’