Pharma industry experts plan antibodies factory to fight pandemics

AS President Trump receives pioneering antibody treatment for coronavirus, a group of pharma industry experts have revealed plans for a fast response biopharmaceutical manufacturing facility.

Lakes BioScience Ltd, formed from a partnership of highly-experienced and industry-respected individuals, is accelerating plans for a monoclonal antibodies factory due to global demand.

The company, formed 18 months ago, plans to deliver a fast, agile, customer-focused approach to manufacturing and process development to help in the fight against Covid-19 and future pandemics.

Derek Willison-Parry, CEO of Lakes BioScience, has more than 30 years’ engineering, operational and strategic experience in the pharma industry working in Europe, China and the US.

Mr Willison-Parry said: “The time is most definitely now in terms of the global and UK need for this facility.

“We have the team with world class skills and capability to respond to this global need in an innovative, customer-focused way, and we have the location.

“This project is building a facility that would be able to manufacture requirements for Covid-19 therapies in a record time.

“If we are successful we will be contributing to controlling this coronavirus and Covid-19 to the extent that we can start to return to normal.

“Now is the time for those who want this to happen in the UK to make sure that together we grasp this opportunity.

“That will mean that in the future, when there is a future public health emergency such as Covid-19 is impacting us now – and it will be a case of ‘when’ not ‘if’ – we as a country will be stronger in our response.

“We will be able to more quickly develop and manufacture the drugs in order to be able to counter such a public health emergency.”

Lakes BioScience projects director Adrian Wallis, who has more than 40 years of industry senior management and executive experience working for ICI and Novartis, says speed is of the essence when it comes to delivering on the opportunity.

Mr Wallis said: “Our ability to deliver a production manufacturing facility from ground to first product in a fast time is something which is really important right now in terms of a response to the Covid-19 pandemic.

“Lakes BioScience can provide the pace and speed of response which is required and we have reinvigorated many of our stakeholders’ views about manufacturing being based in the UK.

“Our proposition is to be able to deliver antibodies to the patients that desperately need them and save lives.

“As well as our innovative ability to build the plant to a short timescale and to run the facility, Lakes BioScience is also perfectly positioned to respond to antibody therapy requirements as they change.”

Pat McIver, one of the founding directors of Lakes BioScience Ltd with more than 30 years of senior-level pharma industry experience, said: “Supply chains are under huge pressure across the world to provide manufacturing capacity for monoclonal antibodies.

“Lakes BioScience is the company which is going to bring to life the notion of a uniquely agile and customer-focused, large-scale, biopharmaceuticals contract development and manufacturing operation in the UK.

“We will build on a rich regional and national capability and create high-value jobs in a fast-growing sector to deliver life-changing and life-saving treatments to patients globally.”

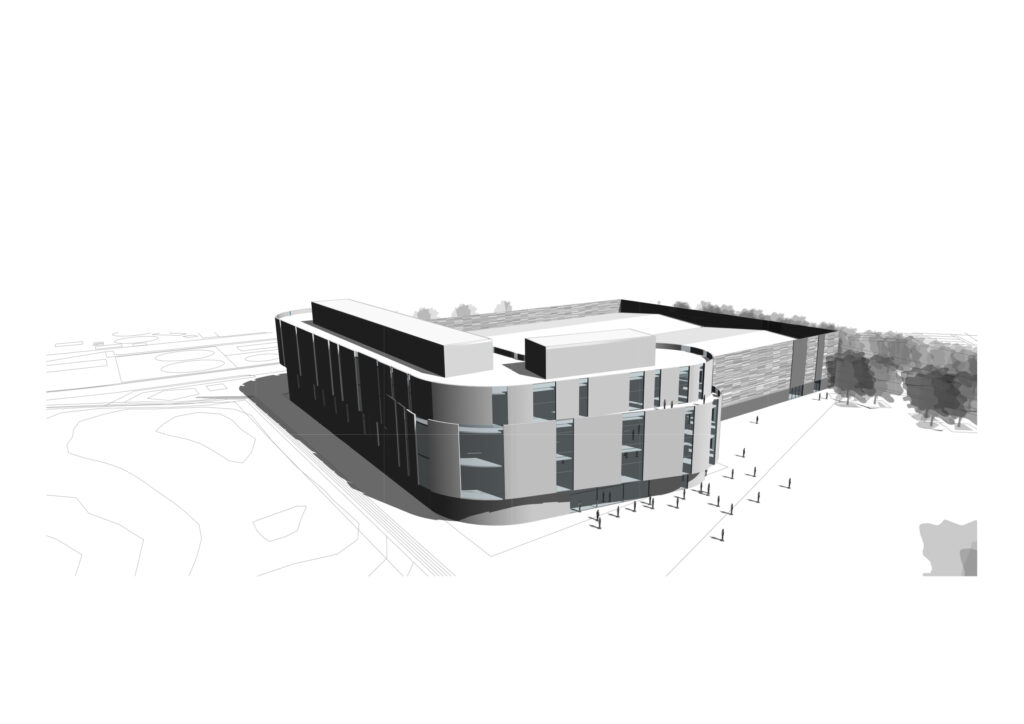

About 250 high value jobs will be created if Lakes BioScience’s plan to build, commission and qualify a £350m biopharmaceuticals site in Ulverston, Cumbria, gets the go ahead.

Lakes BioScience hopes to start work on the site later this year with manufacture of advanced monoclonal antibodies due to start in 2022